Tecnologic 70

Medium Strength Thread Locker

Balanced performance thread locking adhesive offering removable strength for applications requiring occasional maintenance. Perfect for automotive, machinery, and industrial equipment assembly.

Medium Strength Thread Locker

Balanced performance thread locking adhesive offering removable strength for applications requiring occasional maintenance. Perfect for automotive, machinery, and industrial equipment assembly.

Medium strength solution for applications requiring maintenance flexibility

Provides optimal locking force while allowing disassembly with standard hand tools. Ideal for applications requiring regular maintenance access.

Can be removed with standard hand tools without heat application, making maintenance and repairs straightforward and efficient.

Creates effective seal preventing moisture and contaminants from penetrating threaded assemblies while maintaining removability.

Works on all metal substrates including steel, stainless steel, aluminum, brass, and most thermoplastics with excellent adhesion.

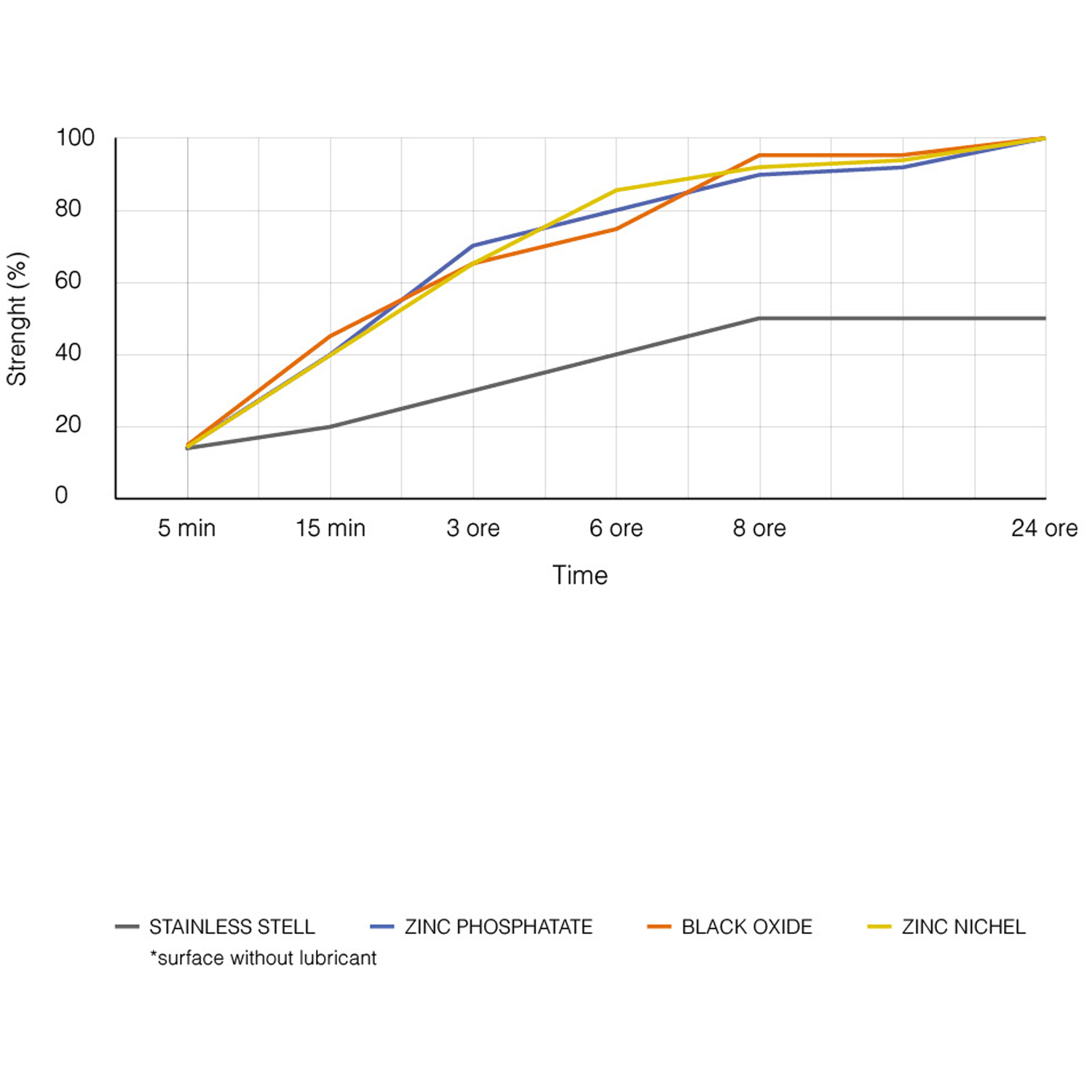

Quick handling strength achieved in 10 minutes with full cure in 24 hours, reducing assembly time and improving production efficiency.

Excellent resistance to vibration loosening, ensuring secure fastening in dynamic applications and high-stress environments.

Perfect for applications requiring regular maintenance and serviceability

Brake calipers, suspension components, and engine accessories requiring periodic servicing

Production machinery, conveyor systems, and equipment requiring regular inspection and maintenance

Household and commercial appliances where occasional disassembly may be required

Electronic housings and control panels requiring secure yet removable fastening

Heating, ventilation, and air conditioning assemblies requiring seasonal maintenance

Construction and power tool assemblies requiring regular servicing and parts replacement

Clean and degrease threaded parts using a suitable cleaner. Ensure surfaces are dry and free from oil, grease, or old adhesive residue.

Apply several drops to the threaded area, ensuring adequate coverage. For pre-applied versions, simply assemble the pre-coated components.

Assemble parts within working time (typically 3-5 minutes). Tighten to specified torque using appropriate tools.

Allow 10 minutes for handling strength. Full cure achieved in 24 hours. Avoid movement during initial cure period.

Quality Management System Certified

Restriction of Hazardous Substances

European Chemical Regulation

European Conformity Standards

Tecnologic 70 is our go-to solution for assembly operations where maintenance access is critical. Easy to apply and even easier to remove when needed.

The perfect balance between security and serviceability. We use it throughout our production line and have seen a 60% reduction in loosening-related failures.

Excellent product for our automotive applications. Provides reliable locking while allowing us to service components without heat or special tools.

Contact our technical experts to discuss your specific requirements and get a custom solution tailored to your needs. We provide comprehensive support from selection to implementation.