Our Product Range

Explore our advanced range of pre-applied coatings, sealants, and solutions designed for enhanced performance, durability, and sustainability in industrial applications.

Adhesives

Pre-applied strong and medium blockers. They block and seal any threaded connection, can be applied to all types of metals and some plastics. During screwing and tightening of the threaded parts, the microcapsules break and with the resins are distributed between screw and lead screw; once polymerization is complete, the product reaches its blocking and sealing power, resulting in excellent resistance to loosening, stress and vibrations.

Sealants

Strong sealants that can be applied on any threaded connection (cylindrical / cylindrical and cylindrical / conical), on all types of metal and on most plastics. During the coupling of the threaded parts, the sealant is distributed eliminating the interference of the threads, ensuring high sealing power for liquids and pressures.

Hybrid Self-locking + Sealant

Strong sealants that can be applied on any threaded connection (cylindrical / cylindrical and cylindrical / conical), on all types of metal and on most plastics. During the coupling of the threaded parts, the sealant is distributed eliminating the interference of the threads, ensuring high sealing power for liquids and pressures.

Cold-applied coating

Suitable for protecting the threaded parts of any threaded connection from adhesion of primers, welds, the low temperatures of the application allow the integrity of the coating and the hardness of the thread.

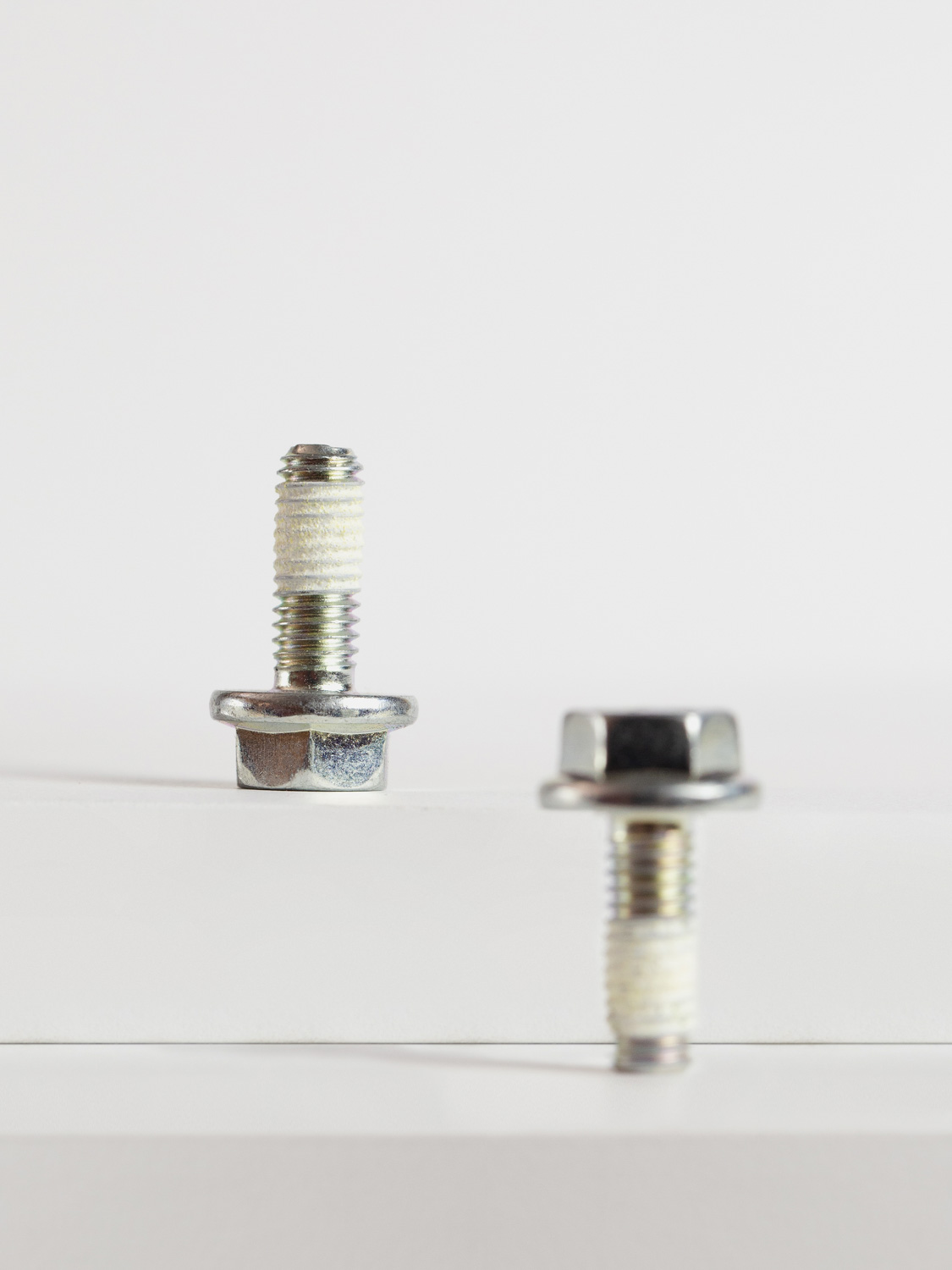

Self-Locking

TECNOFREN® pre-applied, makes any threaded connection Braking / Sealing, Adjustable and Reusable. During screwing, TECNOFREN® is distributed between the thread and the nut screw and eliminates the spaces between the threads, increasing the metal-metal contact and opposing a tenacious and durable resistance to loosening and vibrations. TECNOFREN® takes advantage of the elastic deformation properties of polyamide.

Need Custom Solutions?

Our team of experts can help you find the perfect coating solution for your specific industrial needs.

Contact Our Experts