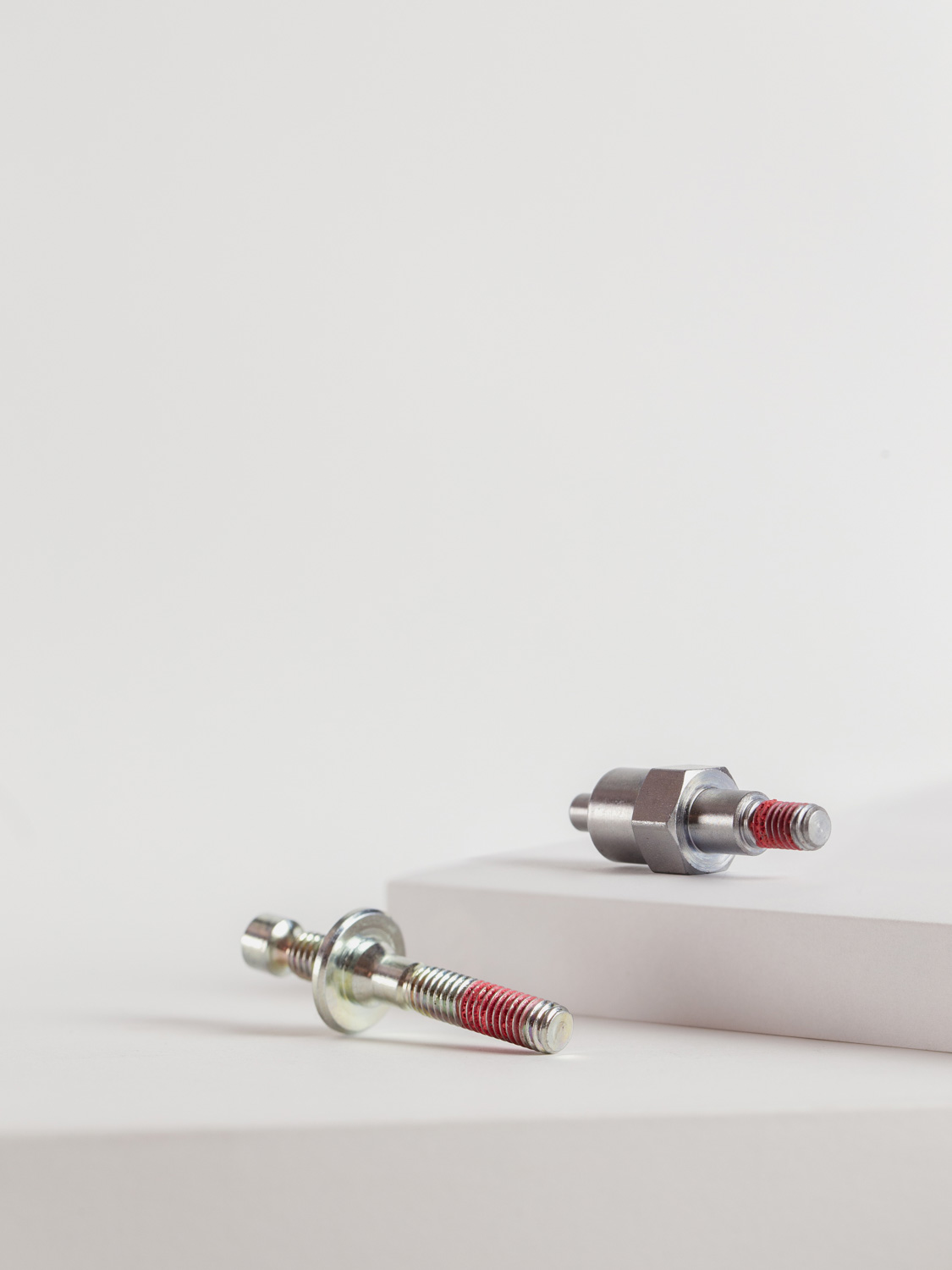

Tecnologic 150 Adhesive

High-Performance Epoxy-Based Thread Locker

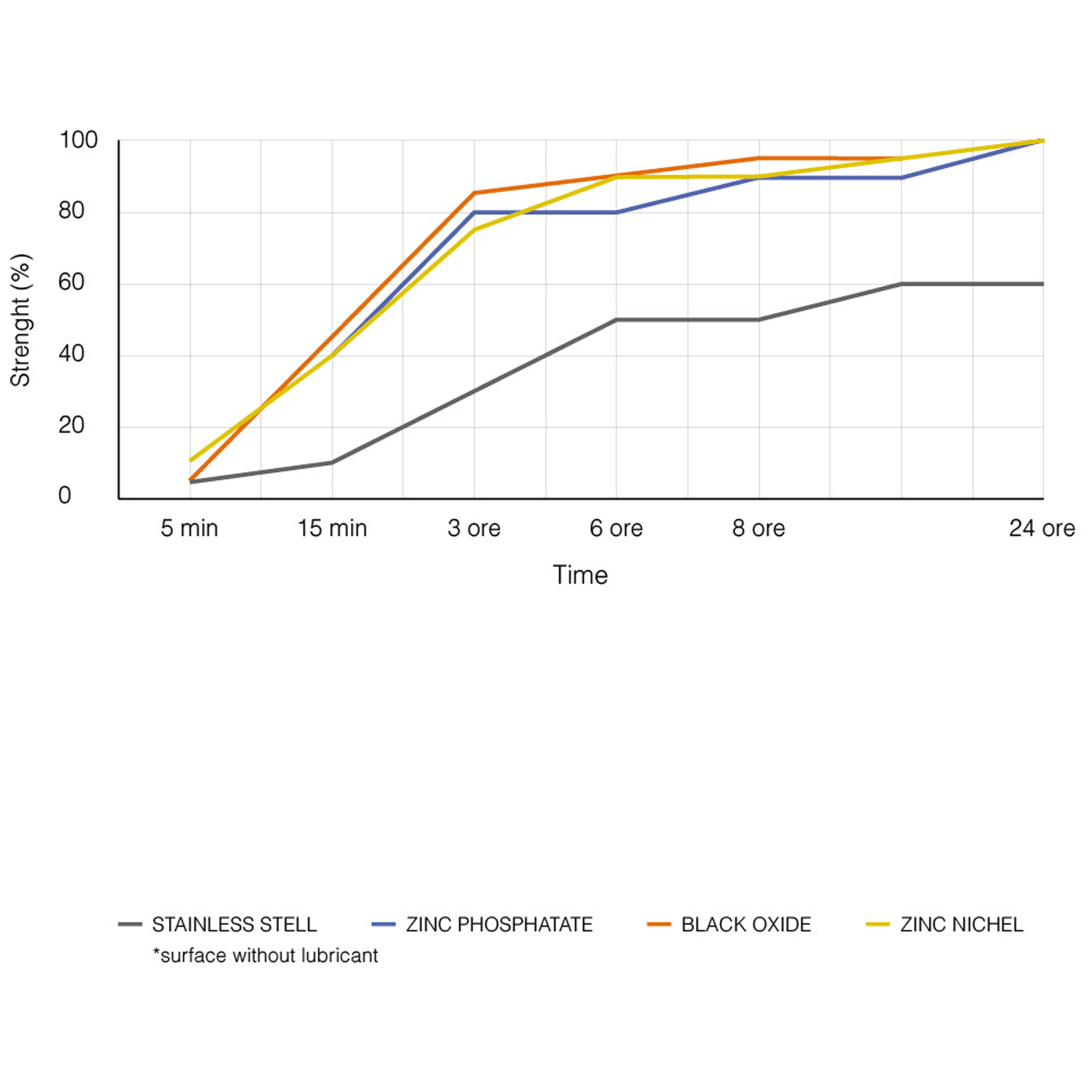

Pre-applied strong blocker designed for maximum resistance to loosening, stress, and vibrations. Ideal for critical threaded connections in automotive, aerospace, and industrial applications.