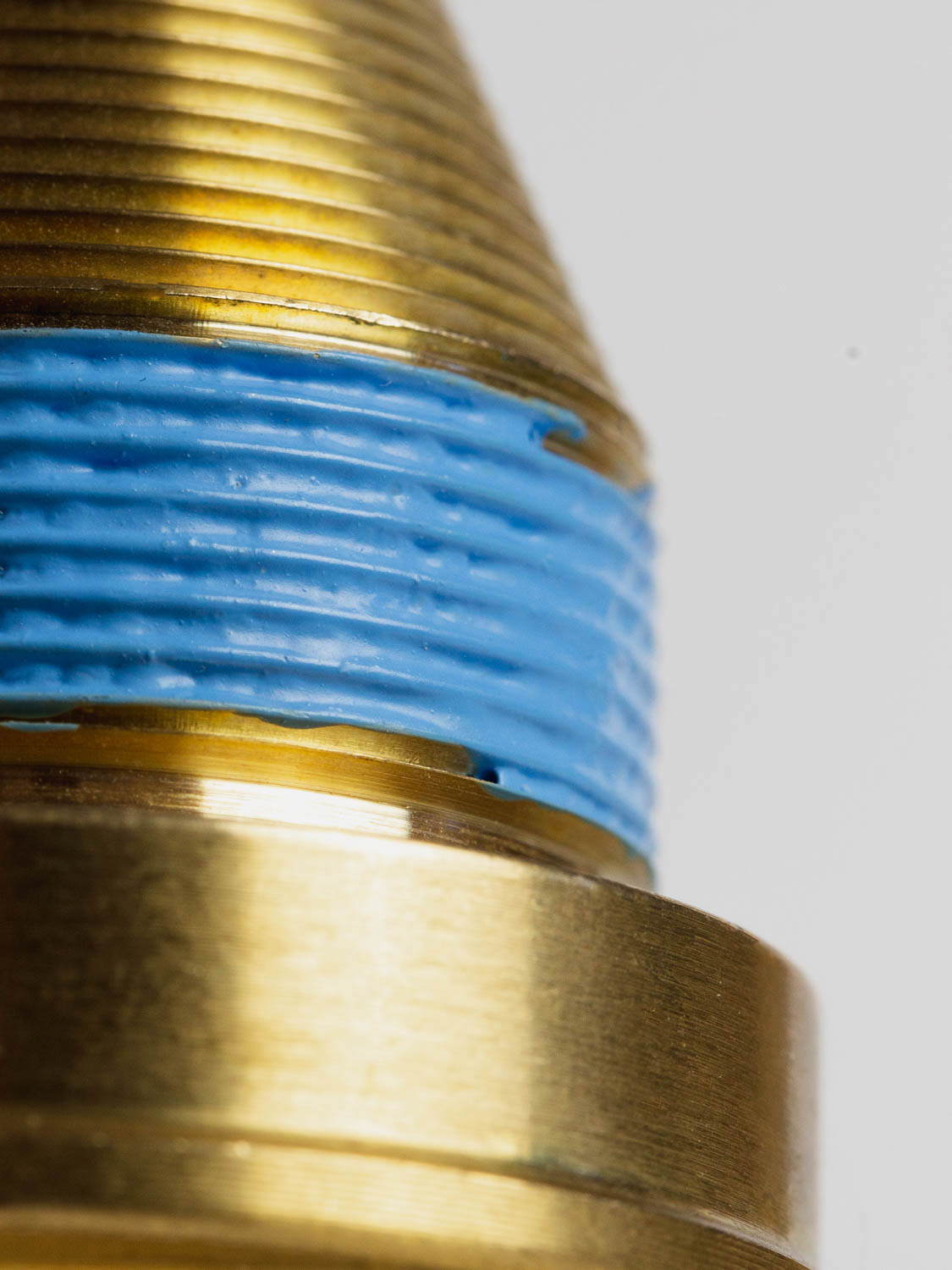

Tecnologic 15

Micro Thread Locker

Ultra-low viscosity thread locker specifically designed for micro fasteners and miniature assemblies. Perfect for electronics, medical devices, and precision instruments where conventional products are too aggressive.